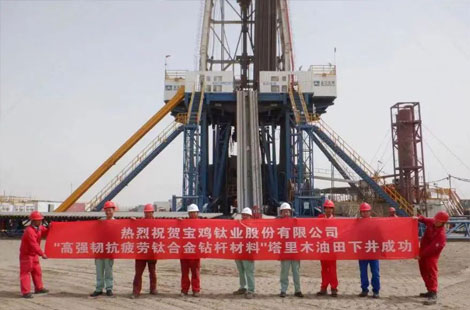

The high-strength and tough titanium alloy pipes developed by Baoti successfully passed the ultra-deep well drilling test

Recently, drill pipes made of Baoti Co., Ltd.’s high-strength and tough titanium alloy pipes successfully completed an 8,000-meter ultra-deep well drilling test in Tarim Oilfield, Xinjiang.

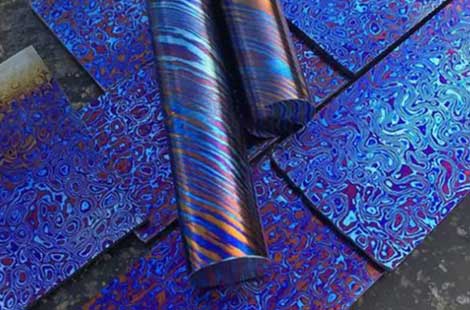

Compared with steel drill pipe, titanium alloy drill pipe has a higher specific strength, and the same equipment can be used for drilling operations in deeper wells; it can reduce torque, further increase drilling speed, reduce drilling time, and reduce drilling costs. At the same time, due to the small elastic modulus of titanium alloy drill pipe, it has better corrosion resistance and erosion resistance, which makes it have obvious advantages in short-radius horizontal well operations and good adaptability in special drilling conditions.

In recent years, Baoti has continuously promoted the research and development of products and technologies in the field of oil drilling. It has cooperated with the China Petroleum Engineering Materials Institute and other units to develop titanium alloy drill pipes for ultra-deep drilling, and has developed a series of series with various strength levels and various typical specifications. Titanium alloy extra long drill pipe. Two titanium alloy drill pipes with a strength of up to 120 thousand pounds per square inch (ksi) and diameters of 88.9 mm and 101.6 mm successfully completed the first downhole test in two ultra-deep wells of 8296 meters and 8579 meters in the Tarim Oilfield, further verifying the titanium alloy drill pipes. The feasibility of alloy drill pipe has promoted the implementation of new materials and new technologies, and provided technical support for the development of ultra-deep energy wells of 10,000 meters in harsh environments in my country.