General Information on Iridium Oxide Coated Titanium Electrode Plates

Iridium tantalum oxide coated are considered the optimum choice as anodes in various industries for their strong corrosion resistance in acid environments, low overpotential for oxygen evolution, great physical stability, and environmental safety. Compared with traditional electrodes, Ir-Ta MMO electrodes present better electrochemical stability under a sulfate/chloride environment and longer service life.

Accumulated decades of coated titanium electrode technology, JAU kept providing our clients with high-quality Ir-Ta MMO electrodes regarding multiple oxygen-evolution systems. JAU electrodes have been applied to industries like copper foil production, electroplating, cathodic protection, organic synthesis, acid solution electrolysis, electrowinning, etc.

Applications:

1. Cathodic Protection

2. Waste Water Treatment

3. Copper Electrowinning

4. Organic Synthesis

5. Chrome Plating

Specification:

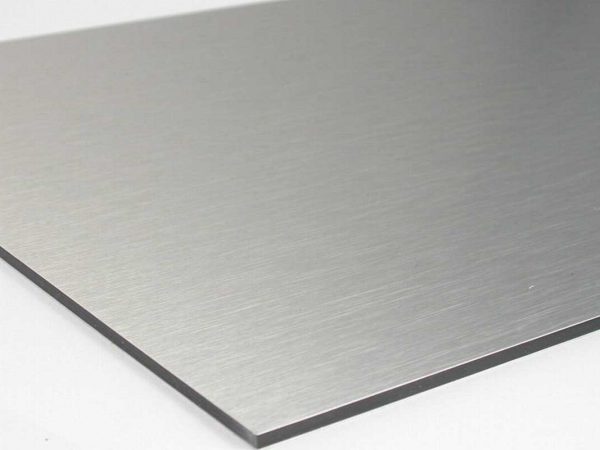

| Anode Type | Iridium Oxide Coated Titanium Anode |

| Material | Gr1 Titanium as substrate, MMO as coating |

| Coating Type | IrO2 + Ta2O5 + X |

| Dimension & Shape | Plate, mesh, rod, or customized |

| Noble metal content | 8 – 25g/m2 |

| Working Parameter | Current density ≤15,000A/m2; PH 1~12;

Concentration Range of H2SO4 <60% Fluoride ion content <50mg/L; Temperature <80℃ |

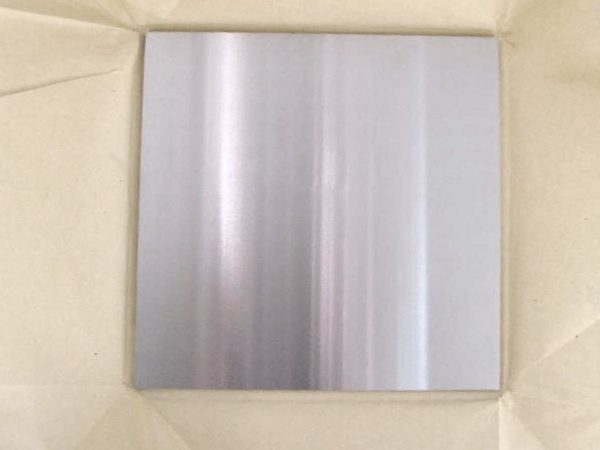

Packaging

Our IRIDIUM OXIDE-COATED TITANIUM PLATES are mostly packaged in a wooden crate with cushioning material to prevent damage to the material during transportation and handling. Many wearing parts are also well-packed in cartons.

Most sizes are kept in stock and can meet any delivery request. Please feel free to contact us here.